Stainless Steel Descriptions

These specifications derive from the Institute of Scrap Recycling Industries (ISRI) and are internationally accepted and used throughout the world to trade commodities.

200 Series Clips & Solids

Consists of all types of clean 200 Series Stainless Steel Scrap Solids, which contain a maximum of .5% copper, free of foreign attachments and other contamination.

300 Series Clips & Solids

17 – 4 Series Clips & Solids

400 Series (Chrome) Clips & Solids

Consists of clean 400 Series type stainless steel clips and solids containing a minimum of 0.5% nickel, 10% chrome, 1% silicon, and .04 phosphorus. Concerns about physical description, grading, additional analysis, and preparation to be agreed upon between buyer and seller.

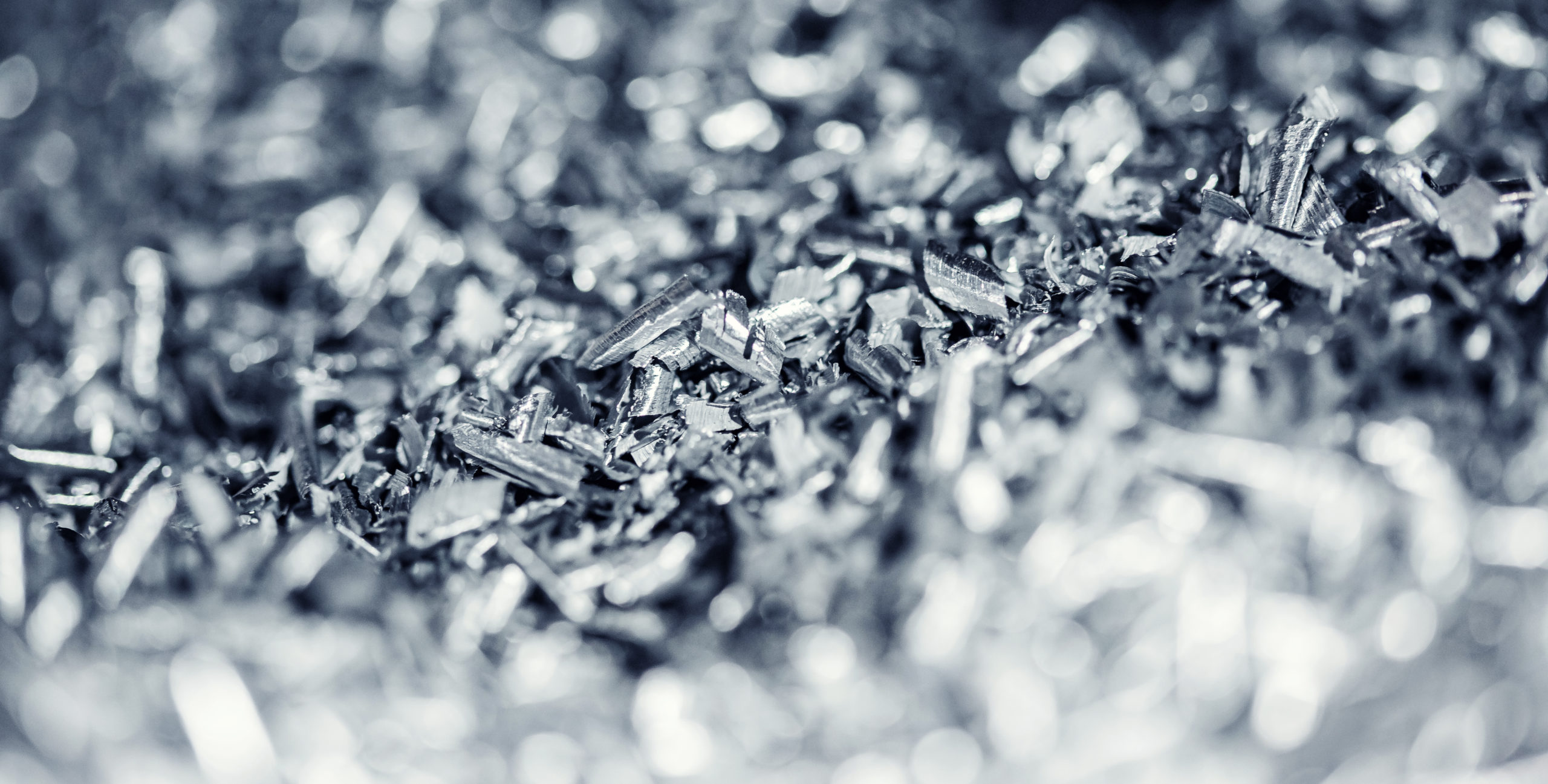

300 Series Turnings

Consists of clean 18-8 type stainless steel turnings containing a minimum 7% nickel and 16% chrome, and to be free of nonferrous metals, nonmetallics, excessive iron, oil and other contaminants. Concerns about physical description, assay, and packaging to be agreed upon between buyer and seller.

17 – 4 Series Turnings

Consist of clean 17-4 alloy stainless turnings containing a minimum 3% nickel, 15% chrome, and have a maximum of .50% molybdenum, 3% copper, .04% phosphorous, and .03% sulfur, and otherwise free of harmful contaminants. Concerns about physical description, grading, additional analysis, and preparation to be agreed upon between buyer and seller.

400 Series (Chrome) Turnings

Consists of clean 400 Series type stainless steel turnings containing a minimum of 0.5% nickel, 10% chrome, 1% silicon, and .04 phosphorus. Concerns about physical description, grading, additional analysis, and preparation to be agreed upon between buyer and seller.

Hi Nickel Alloy Clips & Solids

This includes but is not limited to clean monel, inconel, titanium or hastalloy sheet, plate, bar, tube, pipe or any other wrought scrap. The material must be sorted by alloy type and to be free of nonferrous metals, nonmetallics, excessive iron, oil and other contaminants. Concerns about physical description, assay, and packaging to be agreed upon between buyer and seller.

Hi Nickel Alloy Turnings

This includes but is not limited to clean monel, inconel, titanium or hastalloy turnings. The material must be sorted by alloy type and to be free of nonferrous metals, nonmetallics, excessive iron, oil and other contaminants. Concerns about physical description, assay, and packaging to be agreed upon between buyer and seller.

Nickel Bearing Scrap

Any nickel bearing alloy scrap that contains a minimum of 3% recovered nickel. Nickel content to be determined by recovery after the buyer’s evaluation. Balance of other elements to be discussed between the buyer and seller. Material is to be free of any other foreign material. Final material specifications to be determined between the buyer and seller.

Heat Treat Alloys

Any nickel bearing alloy scrap that contains a minimum of 10% recovered nickel. Nickel content to be determined by recovery after the buyer’s evaluation. Balance of other elements to be discussed between the buyer and seller. Material is to be free of any other foreign material. Final material specifications to be determined between the buyer and seller. Typical alloys used in heat treat plants are HU and HT.

Carbide

Carbide or Tungsten Carbide is a hard, metal containing 6-10% Cobalt. This is a tough material developed for cutting tools. Material is to be free of any other foreign material. Final material specifications to be determined between the buyer and seller.